Tensile Strength and Elongation at Break of Plastic Film

Tensile strength and elongation at break are very important parameters in mechanical testing of plastic film materials, which respectively reflect the deformation and brittleness of the plastic film material during stretching. Plastic film test method include ISO 527-3, GB/T 1040.3, ASTM D882, etc.

• Tensile strength of plastic film (MPa, N)

Tensile strength is the tensile force of a unit cross-section plastic film during stretching and breaking, which indicates the resist stretching ability of the plastic film. Tensile strength reflects the rigidity and toughness of the plastic film. Plastic film with high tensile strength, good resistance to external force, good toughness.

• Elongation at break of plastic film (%)

Plastic film with higher elongation at break, the better the plasticity under stress, is without breaking easily. Conversely, thin plastic film materials with low elongation at break, tend to be brittle.

Ø Elongation at break in the machine direction(MD)

The elongation (%) at break in tension of a stretched film sampled in the machine direction (MD).

Ø Transverse Elongation at break (TD)

Elongation (%) at tensile break of a plastic film sampled in the transverse direction (TD).

Ø Total elongation (%)

The sum of the MD elongation at break and the TD elongation at break.

In general, the TD elongation at break of the plastic film is smaller than the MD elongation at break, as the dimensional change of the plastic film in the transverse direction is small during production). The total elongation is about 1000%.

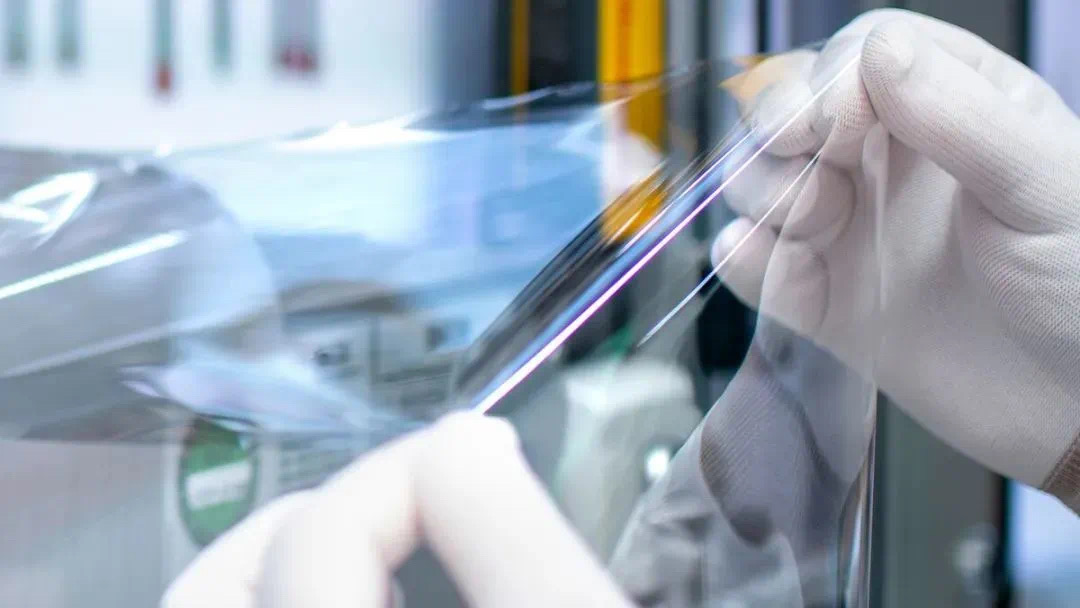

POLYSAN factory is professional in producing types of plastic film PVC film, TPU film, EVA film with high tensile strength and elongation at break.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe