Why is PVC shrink film easy to break?

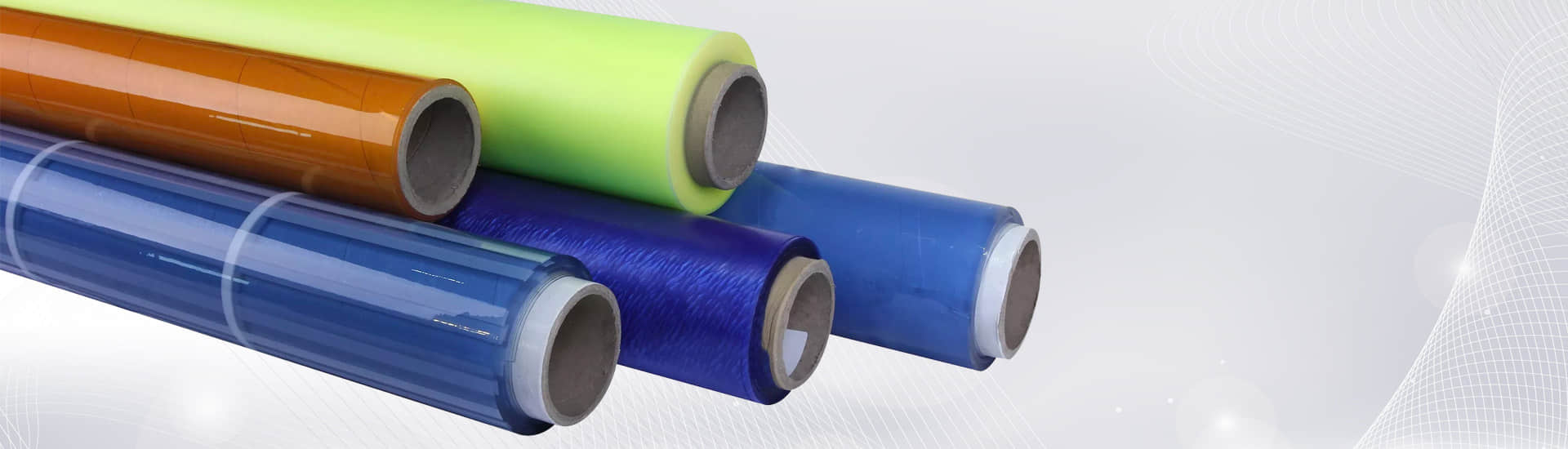

PVC shrink film is very common in the current packaging market, such as the outer packaging of cosmetics, stationery, doors and windows, aluminum, and various stainless steel pipes. Due to the good shrinkage and strong tensile strength of PVC shrink film, as well as the simple and easy operation of packaging, it can be tightly fixed on the surface of the product by heating with a high-power hair dryer or semi-automatic or fully automatic heat shrink machine. However, regarding the outer packaging of some products, some PVC shrink film packaged products are prone to breakage and breakage at a slight touch.

What is the reason behind this?

1、 The quality issue of the shrink film itself. If the temperature is not adjusted properly during production, the product quality will be unstable, the durability will be poor, and it will be fragile;

2、 Shrinkage film made too thin. Some businesses may require manufacturers to make the shrink film thinner in order to save packaging costs, but the thinner shrink film will have too much shrinkage force and easily break;

3、 Improper control of temperature and time during heating;

4、 The product is not brand new material.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe