About the Melting Point and Heat Pressing Working Temperature of Hot Melt Adhesive Film

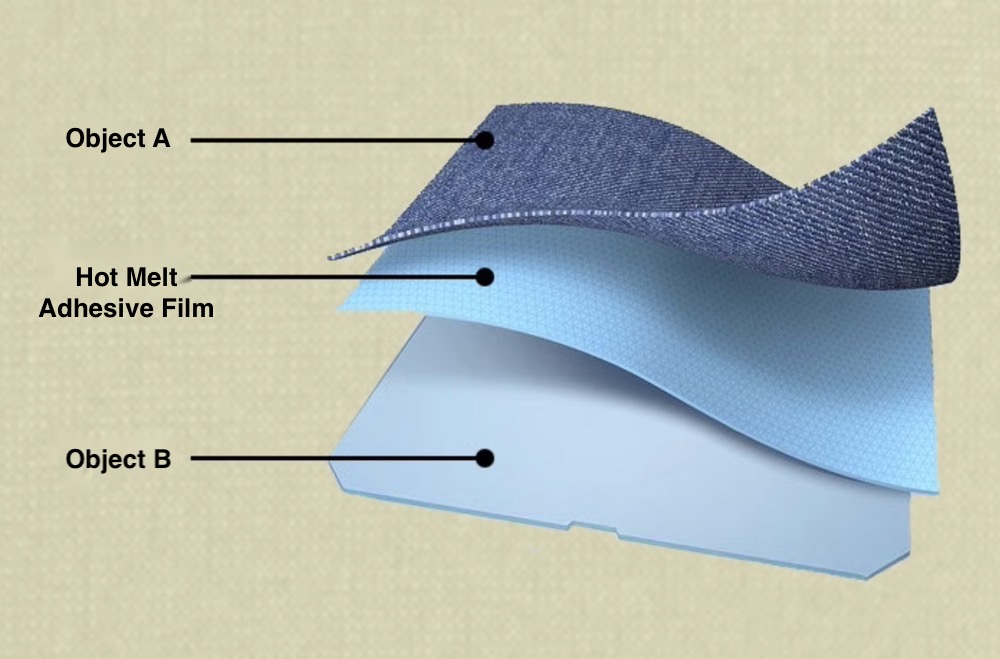

Thin thickness range of the hot-melt adhesive film, between 0.02mm-0.1mm, a slight change in the heat pressing working temperature will directly affect the melting speed, affect the fluidity of the hot-melt adhesive film and the wetting on the material surface.

What is the relationship between the heat pressing working temperature and melting point of the hot melt adhesive film?

The melting temperature indicates the initial melting temperature of the hot melt adhesive film. To ensure the hot melt adhesive film fully melting, the recommended heat pressing working temperature is about 20-30°C higher than the melting point. Low heat pressing operating temperature will slow down the melting speed of the hot melt adhesive film and take long time for material bonding after melting.

Appropriate heat pressing working temperature and heat pressing time ensure the fully melting of the hot melt adhesive film and the bonding strength of the adhered objects, and greatly improve the production efficiency and cost control.

POLYSAN is a professional hot melt adhesive film China factory, we produce and supply types of hot melt adhesive film, TPU hot melt adhesive film, EVA hot melt adhesive film, PS hot melt adhesive film, PO hot melt adhesive film.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe