What about the Blister TPU Film Process?

Different from ordinary casting TPU film, the blister TPU film ensures no break during the vacuum blister process, as the additions of the toughening agent, which greatly reduces the waste of blister material and production costs such as quality shutdown.

The main steps of the preparation method of TPU film used in the blister process are as follows.

1. Appropriate TPU film

Appropriate TPU film, with appropriate thickness, transparency, hardness etc.

2. Place the blister TPU film on the blister mold, be attention for the film direction and position.

3. Heat the blister mold to a certain temperature to soften the TPU film, and absorb on the mold surface.

4. Blister forming

Place the heated mold into the blister molding machine, and absorb the air through negative pressure to make the TPU film closely adhere to the surface on the mold.

5. Cooling and demolding

Remove the blister mold after cooling, easily demolding and obtain the blister product.

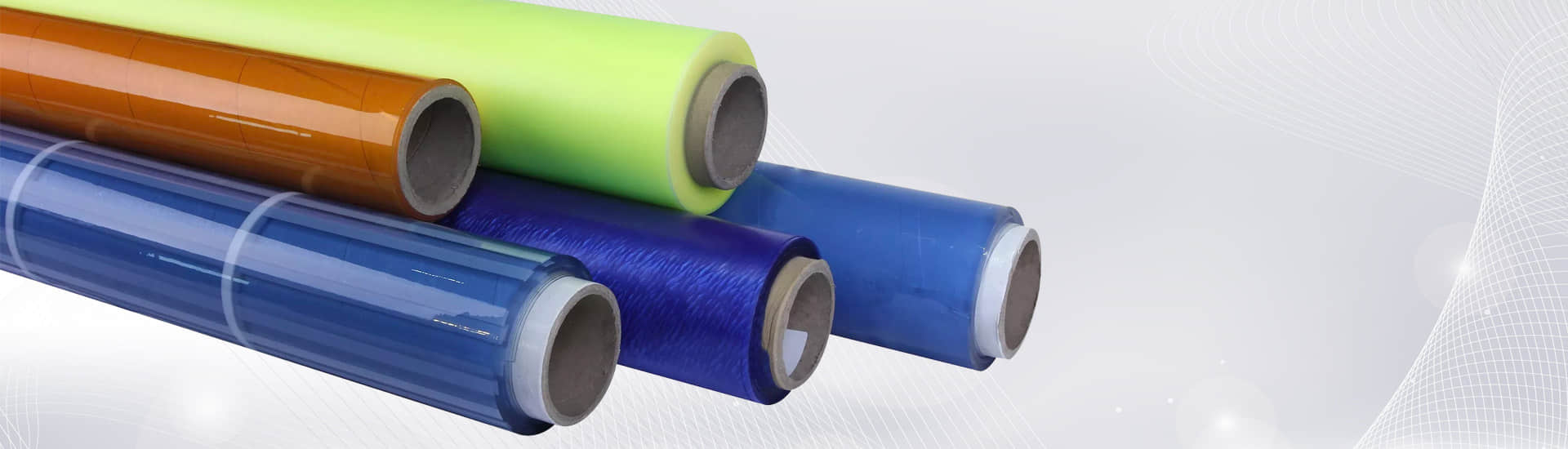

POLYSAN is professional plastic film China manufacturer, we produce and supply blister TPU film used for blister cold-forming and blister thermoforming process, with different thickness and color, personalized and printed with logo is available.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe