The Thermoforming Process of Plastic Film

The thermoforming process of plastic film is a plastic molding technology that heats a thermoplastic plastic film to be soft, then adheres it to the mold surface and uses vacuum adsorption to form. The thermoforming process is widely used in packaging, stationery, toys, advertising and other fields.

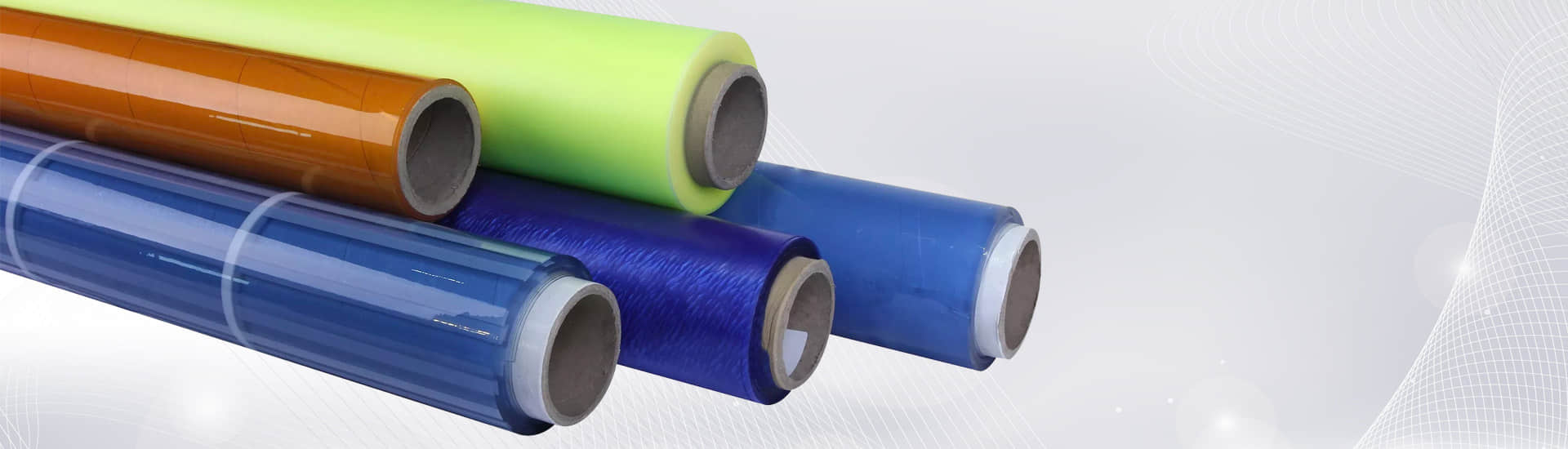

Plastic material can be divided into two categories according to their heating behavior, thermoplastics and thermosetting plastics. Most of the materials used for thermoforming are thermoplastics. like PVC film, PET film, TPU film, etc.

PVC blister film is not easy to fold white, has a small shrinkage rate, fewer crystalline impurities, which has the characteristics of good flatness, waterproof and moisture-proof, good flame retardancy, strong stamping resistance, good wear resistance, not easy to fade, and vacuum plastic does not wrinkle.

PET blister film is colorless, odorless, tasteless, non-toxic, excellent transparent, which has excellent mechanical strength, wear resistance and electrical insulation properties, good creep resistance, rigidity and strength. Blister-formed PET boxes can be directly in contact with food due to their excellent hygiene.

TPU blister film is widely used in shoe sole blister film, equipment protective film, dental braces, etc. due to its excellent toughness, heat resistance, elasticity, cold resistance, and non-toxic and environmentally friendly.

POLYSAN is a professional Chinese plastic film factory, we supply PVC film, PET film, TPU film for different thermoforming plastic product, customized dimension and color .

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe