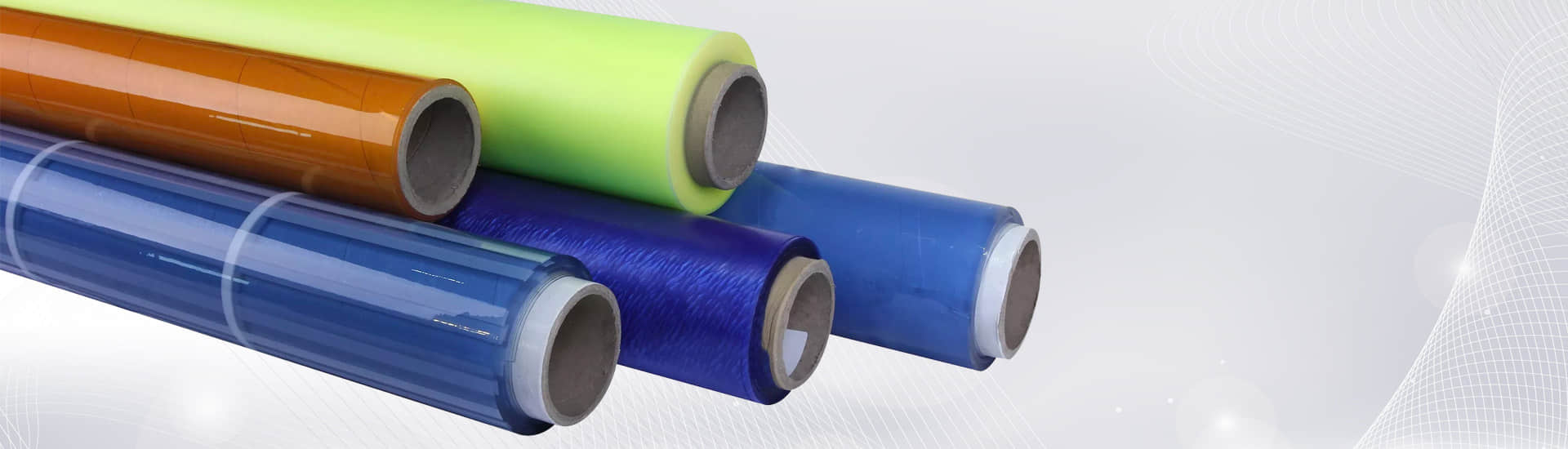

The difference between PET film and PVC film

PET membrane

It is a kind of packaging film with comprehensive properties. It has good transparency and luster, good air tightness and fragrance retention, medium moisture resistance and low moisture permeability. The mechanical properties of PET film are excellent, its strength and toughness are the best of all thermoplastics, and its tensile strength and impact strength are much higher than those of general films. Moreover, PET film has good stiffness and stable size, which is suitable for secondary processing such as printing and paper bag. PET film also has excellent heat and cold resistance, chemical resistance and oil resistance. However, it is not resistant to strong alkali, easy to carry static electricity, and there is no proper anti-static method, so attention should be paid when packaging powdery goods.

PVC membrane

The main component is PVC, which is yellowish translucent and glossy. The transparency is better than that of polyethylene and polypropylene, and worse than that of polystyrene. It can be divided into soft PVC and UPVC according to the amount of additives. Soft products are soft and tough, and feel sticky. The hardness of hard products is higher than that of low-density polyethylene, but lower than that of polypropylene, and there will be albinism at the flexure. Common products: plates, pipes, soles, toys, doors and windows, wire skin, stationery, etc. It is a kind of polymer material that uses one chlorine atom to replace one hydrogen atom in polyethylene.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe